Grease Interceptors

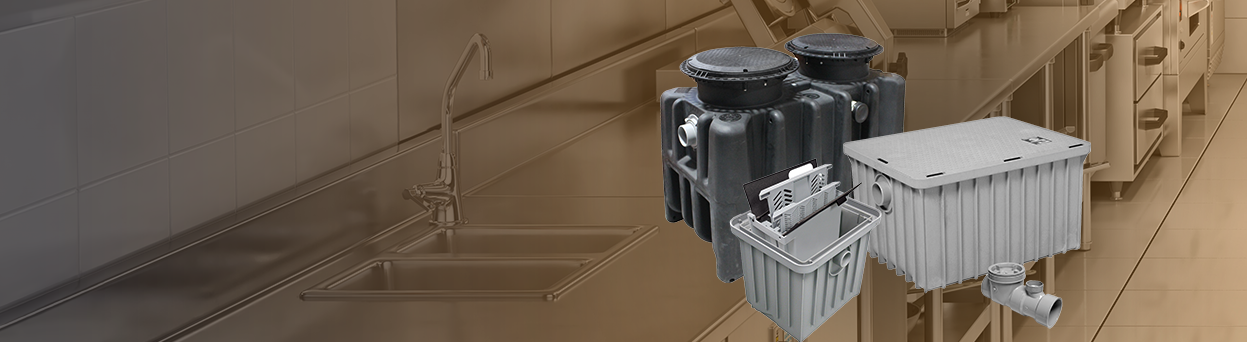

Endura grease interceptors by Canplas deliver industry-leading performance for restaurants, commercial kitchens, and foodservice operations of all sizes. Designed with advanced gravity technology, our grease interceptors offer effective separation of fats, oils, and grease (FOG). Endura units are crafted using durable thermoplastic tanks, employing a combination of injection-molding, foam-molding, and rotational molding. This creates a corrosion-resistant, leakproof solution for long-term grease management.

Why Choose Endura Grease Interceptors?

Endura grease interceptors are built for efficiency, durability, and code compliance across commercial kitchens and foodservice operations. Backed by years of engineering expertise, Canplas offers solutions that consistently outperform traditional systems in real-world conditions.Engineered Performance for Commercial Kitchens

Your restaurant grease interceptor will use gravity separation technology to deliver FOG capture without the limitations of gravity-based systems. Manufacturers craft each unit from high-strength injection molded thermoplastic to prevent cracking, leaking, and corrosion over time. Our top-performing products, such as the Lo-Profile – 25 GPM Grease Interceptor, offer features like tight-sealing lids and an EZ-Open cover latching system for minimal maintenance needs. Unlike metal or concrete alternatives that are prone to rust and structural failure, Canplas grease interceptors maintain their performance and integrity under constant use, reducing service calls and preventing unexpected downtime.Grease Interceptor Sizing

Proper sizing is critical to the performance and compliance of any kitchen grease interceptor installation. Endura offers a wide range of certified units with flow rates from 7 to 150 GPM (gallons per minute), allowing kitchen operators to select the right model based on fixture load, anticipated flow rates, and code requirements. Canplas provides clear guidance and product specifications to help you make your ideal selection. Try our Grease Interceptor Calculators to help find the right grease interceptor for your needs.Grease Interceptors 25% Rule

The 25% rule states that a commercial grease interceptor must be cleaned when fats, oils, grease, or solids accumulate to 25% of the total liquid depth. This threshold can be reached by either 25% grease accumulation, 25% solids accumulation, or a combination of both. Since solids also contribute to this total, using a solids interceptor helps retain solids separately, potentially allowing for less frequent grease interceptor pump-outs, as the 25% volume would reflect grease accumulation alone rather than solids impacting your cleaning schedule. When you follow this rule, you ensure that your Endura grease interceptors maintain peak performance and prevent excessive buildup that could impact wastewater flow and overall plumbing.Grease Trap vs. Grease Interceptor: What’s the Difference?

For many years, smaller grease interceptors were called "grease traps," but the names are not interchangeable. In plumbing, a “trap” means a device with a water seal designed to block sewer gases from entering a building, while a grease interceptor’s primary role is to separate fats, oils, and grease from wastewater. Not all grease interceptors include a water seal, so calling them “traps” can be misleading and may create health and safety risks by allowing dangerous sewer gases into buildings. That’s why terminology has shifted to more accurate names like “hydromechanical grease interceptor.” Both the Uniform Plumbing Code (UPC) and International Plumbing Code (IPC) previously allowed grease traps to double as fixture traps under certain installation conditions, but this contradicted the rule that plumbing fixtures must not be “double trapped.” The codes evolved to eliminate this ambiguity by:- Removing the term “grease trap” and instead using “grease interceptor.”

- Introducing the terms “hydromechanical grease interceptor (HGI)” and “gravity grease interceptor,” based on how they operate and are sized.