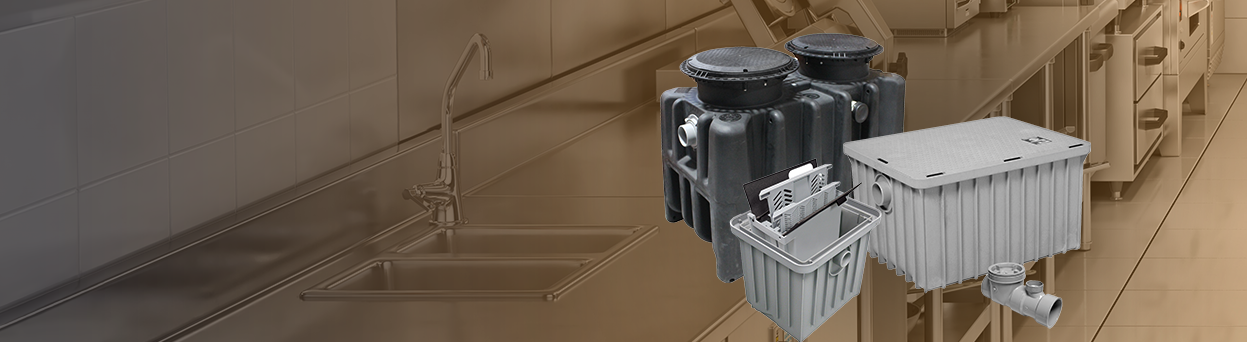

Solids Interceptors

For applications where solid materials (sand, grit, food particles) are at risk of entering the wastewater stream, Endura offers a full line of solids interceptors. In addition to their various stand-alone applications, solids interceptors can be used upstream of grease interceptors in food service applications. Grease interceptors achieve peak performance when kitchen waste and debris are separated from the grease, reducing the risk of costly clogs and backups. Available in various models, including an XL unit, these interceptors feature removable filter screens and an injection-molded tank and lid made from corrosion-resistant engineered thermoplastic for durability in challenging conditions.

Endura Solids Interceptor: Efficient Solutions for Wastewater Management

The Endura solids interceptor that Canplas offers is engineered to capture basic debris before it enters wastewater systems, protecting plumbing and improving facility drainage performance. Crafted from corrosion-resistant thermoplastic, each solids interceptor delivers reliable sediment and particle separation from commercial kitchens, maintenance areas, and other high-use environments. With multiple sizes available and easy solids interceptor installation, Endura provides durable, code-compliant solutions for effective wastewater management.Understanding the Purpose and Maintenance of Solids Interceptors

By isolating solid waste in a building’s wastewater system, solids interceptors and plaster traps help prevent clogged pipes, reduce maintenance issues, and improve overall plumbing efficiency. By installing a solids interceptor, you ensure that only grease and water flow into your main tank. This frees up capacity, prolongs the time between pump-outs, and improves the overall efficiency of your wastewater management system. However, you can’t just install this solution and forget about it. Cleaning a sediment interceptor involves removing the lid, lifting out the internal screen or basket, and disposing of the collected material. Doing this regularly helps ensure consistent performance and extends the life of the plumbing infrastructure.Solids Interceptors vs. Grease Interceptors: What You Need to Know

A Z1180 solids interceptor refers to interceptors built to ASME Standard A112.14.3 and CSA B481 requirements, ensuring quality performance in commercial settings. Sediment traps for sinks specifically separate solids from wastewater, unlike grease interceptors, which are designed to capture fats, oils, and grease. While both grease interceptors and solid interceptors protect plumbing systems, they manage different types of waste entirely. In many commercial kitchens, a solids interceptor is installed upstream of grease interceptors to maximize system protection while maintaining compliance.Choosing the Right Solid Interceptors for Your Facility

Selecting the proper solids interceptor depends on the type and volume of debris generated by your facility’s operations. Facilities handling heavy materials like sand or plaster may need larger-capacity units with fine filtration screens. For localized applications, an under-sink sediment trap offers compact protection without disrupting workspace layout. Some key factors to consider include:- Debris type and particle size

- Fixture connections and flow rates

- Required maintenance intervals